When adhesive is applied using a notched trowel, the material is distributed in defined ribs. The geometry of the notch pattern determines rib shape, spacing and height – and therefore the amount of adhesive applied per square metre.

Consistent notch geometry ensures predictable adhesive consumption and reliable wetting of the substrate.

Precise dimensions enable uniform results across tools, batches and production series.

High manufacturing accuracy and clean edges support smooth application and long service life.

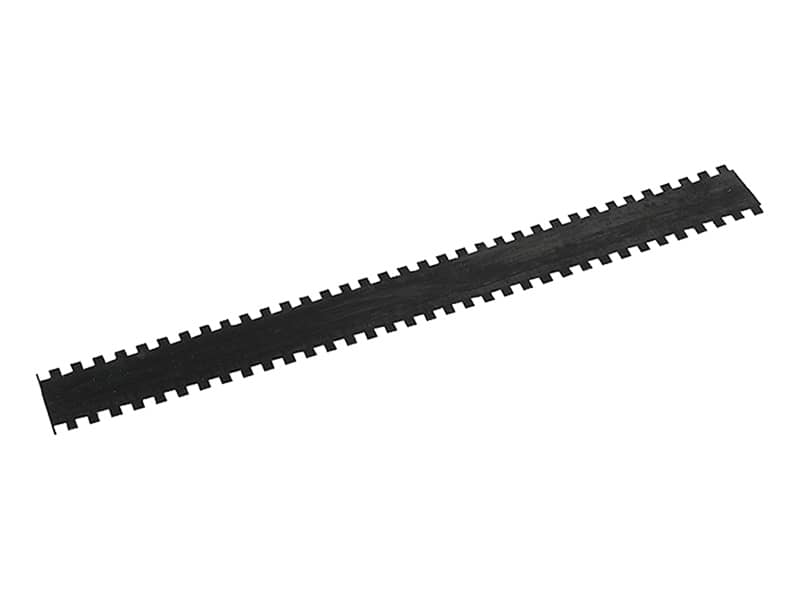

Depending on the application, notched trowels, adhesive trowels or replaceable notched bars are used. The notch pattern defines geometry, material flow and repeatability of the application.

Item No. nbsp;421028

Item No. 4201XX (XX = version)

Item No. 414028

Item No. 413028

Various versions, see notching table.

Notch patterns are described using defined dimensions. In addition, notch shapes vary depending on the application and the desired adhesive coverage.

On this page, dimension ""” consistently refers to the notch spacing (pitch).

Inside edges and tips are rounded due to manufacturing constraints. Sharp internal geometries are not intended. Small internal radii (e.g. approx. 0.2–0.3 mm) at inside tips and edges are typical.

The notch patterns and dimensions shown here are based on the recommendations of TKB Data Sheet 6 ("Notch patterns for floor covering, parquet and tile installation") and serve as a technical reference. They do not represent a binding standard.

Defined tolerances and suitable materials are essential for achieving repeatable results. This is particularly important for series production, OEM projects and industrial applications.

a ± 0.1 mm

b ± 0.1 mm

(a + b) ± 0.1 mm

c ± 0.1 mm

γ ± 0.5°

These values serve as a reference for dimensional accuracy and comparability of notch patterns.

For long service life, the use of spring steel is recommended, with a minimum hardness of 46 Rockwell or higher. The thickness of the steel sheet should not be less than 0.5 mm.

Tools or notch patterns that comply with these specifications and are subject to quality control may be marked as follows: Manufacturer / TKB notch code / year

When selecting suitable notch patterns, adhesive manufacturers assume that the trowel is guided at an angle of approximately 60° to the substrate. At a flatter angle, the required amount of adhesive may not be achieved.

The degree of wear should be checked regularly, for example by visual comparison with a new notched bar or by monitoring adhesive consumption per area. Inspection is recommended every 50–80 m², depending on the substrate and notch shape.

Are you planning a production series or do you require a custom notch pattern based on a drawing? We support you with geometry design, material selection and manufacturing details – from prototypes to series production.

Additional geometries, modifications and custom notch patterns are manufactured according to customer specifications.

The design of the notch patterns shown is based on the recommendations of TKB Data Sheet 6. Dimension definitions, geometries and tolerances follow these guidelines and are implemented by us using appropriate manufacturing processes.

Meaning of the column values shown in the notching cards (dimensions in mm, angles in °).

On this page, dimension “a” consistently refers to the notch spacing (pitch).

Series: A

Series: A

Series: A

Series: A

Series: A

Series: B

Series: B

Series: B

Series: B

Series: B

Series: B

Series: B

Series: B

Series: B

Series: B

Series: B

Series: B

Series: B

Series: B

Series: B

Series: B

Series: C

Series: C

Series: C

Series: C

Series: C

Series: S

Series: S

Series: S

Series: S

Series: R

Series: R

Series: R

Series: M

Note: If you cannot find a specific notch pattern or require different dimensions, we manufacture custom notch patterns according to your specification. The dimension definitions a, b, c and γ are explained in the section Dimension definitions and notch shapes.

Are you developing your own systems or do you require a defined notch pattern for your series product? We manufacture notched bars and notched tools to standard specifications – and produce custom geometries based on drawings, samples or your technical specification.

Send us the notch code or a drawing – we will get back to you with any questions, a feasibility check and a quotation.